Cobra™ Ultimate™ Carbon Shield™

Material: Carbon Shield™

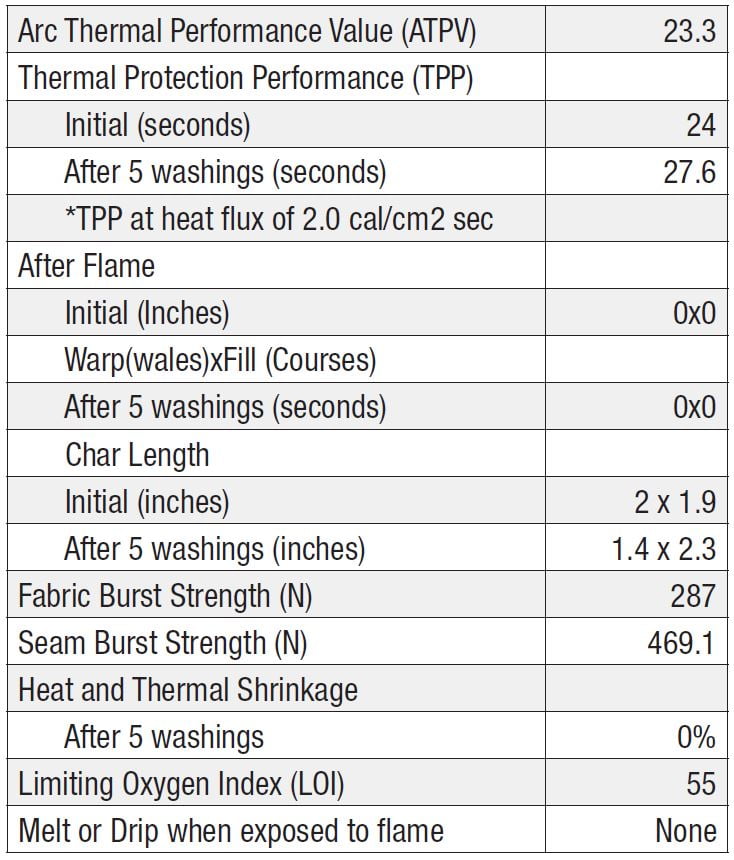

Arc Rating: 23.3 HRC Rating: 2

Design: Extra Long Double ply hood throughout

• X-Long length covers chest, shoulders and shoulder blades

• Flat-stitched seams

• X-heavy 1/2” wide elasticized face opening

• Cover stitched bound drape

• Double-ply hood throughout

• UL Classified to NFPA 1971: Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting – Current Edition

Features

Details

Carbon Shield is a flame resistant fabric breakthrough based on carbon fiber technology. Considered the ultimate high-tech fabric for thermal protection and comfort. During the torch test, after about 5 seconds, traditional FR fabrics combust, severely shrinking and charring. Carbon Shield remains dimensionally stable even after 90 seconds, giving you the extra time you need to get out safely. Properties of Carbon Shield include:

• Non-flammable: If exposed to extreme heat or flame fabric glows but won’t burn. It retains a certain tenacity at temperatures exceeding 2300°F for over 90 seconds.

• Non-melting: Absolutely melt-proof and doesn’t become stiff. It remains soft to the touch after being exposed to fire.

• Arc Resistant – ATPV 23.3 HRC 2

• Superior Protection from Welding Sparks and Molten Metal: Resists pin holing from welding sparks and splatter. Sheds most molten metals and will not melt, ignite or burn even in the most severe levels of exposure offering unparalleled protection from molten metal splash.

• Non-Shrinking: The space between the clothing and the body reduces and protects against burns. Carbon Shield™ is almost totally non-shrinking when exposed to flame and heat.

• Forms No Openings: If an opening should form, fire comes into direct contact with the body and increases the possibility for burns. Because fabric doesn’t melt or stiffen and is non-shrinking, it develops no openings.

• Deposits No Tar: When clothing melts or stiffens and decomposes in a fire, it deposits a by-product tar in the form of a liquid, which has a similar effect as melting increasing the risk of burns. Carbon Shield™ deposits no tar.

• Low Heat Conductivity – (Disburses Heat Energy): In order to ensure the time to escape from fire, clothing must possess the property of delaying the transmission of heat. PGI’s Carbon Shield™ has a low heat conductivity.

• Infrared Non-Reflective: Excellent for police/swat teams as well as military applications.

• Natural Black Color Hides Soil

• Lightweight Yet Excellent TPP: Weighs only 6.5 oz. /sq. yd. which is over 20% lighter than most NFPA compliant hoods, yet still has excellent Thermal Protection Performance (TPP) rating of 28.

• Excellent Stretch & Recovery Properties: 1 x 1 Rib knit construction. Knit to allow 200% stretch for maximum stretch and recovery.

• Fabric has an excellent moisture regain (approx. 8%) and wicks moisture away from the skin to the outer shell, enabling it to evaporate at a rapid rate. The aspect of wicking moisture off the body not only offers a more comfortable garment but also improves protection.

• Chemical Resistance: Excellent resistance to organic solvents, weak alkalis and weak acids.

• Excellent Shape Retention: Unlike some hood fabrics which don’t hold their shape after laundering, Carbon Shield™ has extremely low shrinkage and looks virtualunchanged after repeated washings and dryings. Also, after laundering fabric showed no change in flame resistance or thermal protection.

C Odor Absorbing Qualities: Has ability to absorb and neutralize unpleasant odors, a considerable advantage when opportunities for washing are limited.

• Resistant to Ultra Violet Rays: Will not fade or weaken when exposed to UV rays.

• Highest Limiting Oxygen Index (LOI): Flame resistance is commonly measured by LOI, the amount of oxygen needed to support combustion. The higher the LOI value, the more flame resistant the material. Carbon Shield™ has an LOI which is over 50% higher than Nomex and 33% higher than PBI FR Rayon blends.

• Meets NFPA Requirements: UL Classified to meet the current hood requirements of NFPA 1971, Standard on Protective Ensembles for Structural Fire fighting and Proximity Fire Fighting (Classic, Ultimate and Elite Styles).

• Meets CAL-OSHA REQUIRMENTS: Passes Fed. Test 191, Method 5903.2: CAL-OSHA Sections 3406(d)

• Complies with OSHA Rule 29 CFR Part 1910, 269

• Meets CE Requirements: Meets or exceeds Draft European Standard prEN 13911 (Classic, Ultimate and Elite Styles).

• Compliant with NFPA 70E – Current Edition: Meeting the performance specifications of ASTM-F-1506 (On double ply hoods)

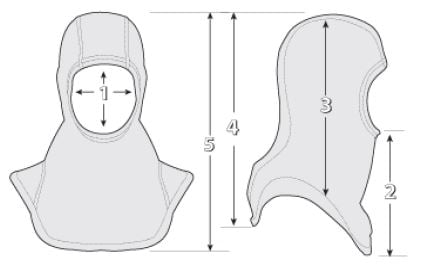

- 1) Face opening is circular and measures between 4.6” to 5.6” in diameter.

- 2) Length of hood below face opening approx. 12”.

- 3) Length of hood at side from top to bottom approx. 17”.

- 4) Length of hood at front and back from top to bottom approx. 19½”.

- 5) Length of hood at front top to bottom approx. 20”.

Size: One size hood fits all.

Labeling and User Information:

Each hood is clearly labeled to identify material contents, NFPA acceptance, UL Classification, Date of Manufacture, and Care Instructions. Included with each hood is a complete users information guide.

Meets or Exceeds Industry Standards

Material

Fabric

• Both outer shell and lining are a blend of Meta-Aramid/Lenzing FR®/High Tenacity Nylon – approx. 6 oz sq yd.

• 1 x 1 rib knit fabric – knit to allow approx. 130% stretch for maximum stretch and recovery.

• Calendared to minimise laundry shrinkage.

Stitch Types and Seams

• All stitching conforms to federal Standard 751 Specifications (FEDSTD-751).

• Major seams are flat seam assembled, stitch type 607.

• Drape attachment to top is done with stitch type 401 and reinforced with stitch type 605

• Elastic in face opening is erged in with stitch type 503 and reinforced with bottom cover-stitch, stitch type 406.

• Binding is applied with bottom cover-stitch, stitch type 406.

Thread

All seams are sewn with 100% Nomex thread size Tex 40.

Construction

• Composed of two layers throughout.

• For a contoured fit the hood is seamed from top of face opening to back of head.

• Face opening is circular in shape and serged with x-heavy duty ½” wide elastic around the perimeter. The elastic is then folded back ½” and cover stitched. The face opening stretches a full 16” (which is 25% more than conventional hoods) for easy donning and a snug fit around face of SCBA mask. Face opening maintains original shape after repeated launderings.

• The bottom edge of hood is bound with self-material bias binding.

• Gusset added at side seams to provide complete shoulder coverage and smoother drape.

Performance Features

UL classified to meet or exceed NFPA 1971 – Current Edition; Compliant with CAL-OSHA, Sections 3406 and 3410(d) and OSHA Rule 29 CFR, Part 1910, 269. Compliant with NFPA 70E Current Edition and meets performance specifications of ASTM-F-1506. ARC Rating: 23.3 – Hazard / Risk Category: 2.

Fabric Performance Values

Technology

Related Products